DIP / SMD / COB LED

Since

LED lighting was invented, it has evolved overtime to become one of the cost

effective and energy efficient lights around. Today there are more than one

model of LED technology is available in the market. LED technologies like DIP,

SMD, COB LEDs are created with unique features ideal for different

applications.

DIP

LED:

DIP ( Dual-in-Line-Package) LEDs are

traditional LED lights. They look the most like a traditional light with chip

encased in a hard plastic cylindrical body and a spherical top generally used

with straight parallel connecting pins.

Each

DIP LED has a single chip and semiconductor die that emits light when supplied

with electricity. Each DIP LED is only capable of producing one color. That is

why it is commonly combined with the other two differently colored DIP LEDs to

achieve the RGB ( red, green , blue ) color scheme.

This

type of LED produces around 4 lumens per single LED, and input power is 5V to

12V. The eam angle of DIP LED reaches 60 degree.

The

DIP LED technology is suitable for harsh environments. It is protected with

hard Epoxy case and a circuit board that gives additional resistance against

impacts.

DIP

LEDs are heavier than other LED types, making them unsuitable for LED displays

with smaller pixels.

DIP

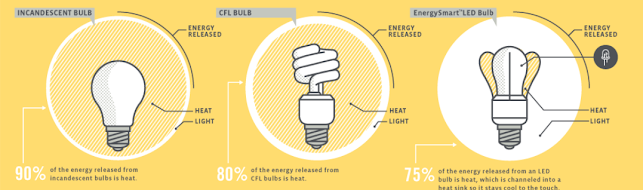

LED can help you to save energy upto 80% compared to traditional lights like

fluorescent bulbs.

DIP

LED is commonly used as a light indicator for many electronics and home

appliances like computers, television sets, dashboards etc. DIP LEDs are also

used for decorative purposes.

SMD LED:

SMD stands for Surface Mounted Diode and are much smaller and efficient LEDs than DIP chips. They are popular due to their versatility and are typically mounted and soldered onto a circuit board. In an SMD module, the three colors of LED bulbs are encapsulated into one slim case which is directly soldered onto a circuit. The red, green and blue LEDs are visually regrouped into a single point, producing either the color black, or white. This point is either a circle or a square, which has a diameter of just a few millimeters. These modules can be made to as small as 1mm in size.

Because

these diodes are mounted onto only one surface on the board, they are small and

can be placed closer together. Closer placement results in a much higher

resolution as compared to DIP modules.

It

can produce 50-100 lumens per watt.

SMD

LEDs are labelled with 4 digit number. And number represents size of LED. First

2 digit refer to LED module length, last

2 digits refer to the height. Measurement are 10th of the

millimetre. SMD 3535 measures 3.5mm(L) x 3.5mm(H).

SMD

LEDs are flat that allows you to have a light & nice looking appearance.

SMD modules are lightweight, have a

much wider viewing angle and are more energy efficient.

SMD requires a circuit for each diode

included in the chip.

Combination of LEDs over small area

also produces certain amount of heat, to maintain long life of LEDs this heat

has to be dissipated.

COB LED:

COB (Chip On Board) LED has 3 LED

chips (each RGB color) directly soldered on an LED substrate. Multiple LEDs

embed within the inner substrate to produce one LED module.

With COB package design, LED chip looks like one LED lighting panel rather than multiple LED lights put together. COB LED chips can occupy less space but still achieve highest potential.

The COB technology offers higher

reliability, as process does not require any supports and brackets, which as a

result reduces failure. The COBLED display is more resistant to humidity, dust,

rust, & moisture.

COB LED supports direct attachment to

heat sink, without attaching to PCB circuit board, results in better heat

dissipation.

COB chips can offer a much higher

amount of lumens, often be well over 100 per watt.

COB LEDs offer a wide range of

applications, various lamps such as street lights, downlights, spotlights, and

other electronic devices such as cameras and smartphones.

Overall, the COB LEDs have high power

light-emitting diodes, which give you higher

light efficacy and lighting effect. Overtime, there is minimal light

loss as COB LEDs do not need the other lenses and packaging style.

The COB LED’s color uniformity is

less than that of the SMD LED.

Since the creation of the COB chips, a variant has appeared called MCOB or “Multiple Chip On Board”. It is multiple COB chips together in series.

Comments

Post a Comment