ROLE OF OPTICS IN LED LIGHTS

The optics in any LED lighting system is crucial elements of that system’s performance, as they alter the directionality and intensity of light from the LED source. Optics in LED lighting can include the spatial distribution of light from the diode itself, and the reflectors, lenses, and holders that cut off or limit output light with mechanical blocking devices. Facilities that install LED lighting systems will use different optics in LED lighting, for example, to control the beam angle of the output light, to create either crisp-edged or diffused light, or to concentrate light in certain areas while limiting it in others.

LEDs

are directional lighting, illuminating only 180 degrees. This is attributed to

the design of an LED, as you can see below, a light emitting diode consists of

one or more die, mounted on a heat-conducting material, with the primary optic

enclosing the die. Therefore, the maximum angle LEDs can emit is 180 degrees as

the substrate is on the back side of the die.

The primary

optics of an LED is a little protective dome. And it’s usually over the

diode. The optics serves to protect diode and shape the output of the small

diode.

Along

the center axis, the LED emits 100% of its relative luminous intensity and will

lose intensity the farther away you move from the center. It is obvious

when you are losing light output over the spectrum, that a secondary lens or

optic is needed to intensify that light and use the brightness and efficiency

of LEDs to their full capacity.The light from the LEDs primary optic is

still too broad for most applications, lacking intensity over distance. This is

why most LED fixtures use secondary optics.

To

alter the beam of light coming from the LED source, lighting fixtures require

at least some type of secondary optics. The secondary LED optics takes all the

light within a given bulb or fixture, and magnifies the intensity towards the

target, based on how the optics is designed. Secondary optics is not only made

to collimate the light, but is sometimes also used to improve color uniformity

and light distribution within the targeted area.

There

are four types of secondary LED optics—lenses, reflectors, TIR (total internal

reflector) optics and TRIMS.

LENSES

Lenses come in different materials,

like polymethyl methacrylate (PMMA), also known as acrylic, polycarbonate,

silicone plastic, and polybutylene terephthalate (PBT). Most lenses use optical

grade PMMA and achieve a lighting efficiency of 90%. Optical grade PMMA lens

material is harder and more fragile compared to polycarbonate and allows for

the use of high current and high-temperature conditions. Apart from PMMA,

polycarbonate material also offers excellent optical characteristics.

Various

properties of LED lenses enable the desired lighting effect and precise control

over the beams of light. They come in various shapes and sizes—for example,

round, square and hexagonal. The lens directs light from the centre of the

source to the reflector

Aside from altering the angle of the

light being emitted from the LED and therefore altering the beam angle, the

lens is generally of two types:

Clear lens which creates a distinct spot light effect good for impact ‘accent’

lighting in fashion outlets, jewellers, etc., but can create glare so correct

placement is important, generally only used in commercial applications.

Opaque lens or Fresnel lens which acts as a diffuser to soften the light for general ‘ambient’ type

lighting for residential and general commercial lighting applications where

glare needs to be reduced.

The limitation of the opaque or

Fresnel lens is that there is a reduction in lumens depending on the opacity

and quality of the lens. The Fresnel lens can also have the effect of

scattering the light such that narrower beam angles can seem slighting wider,

for example a 45° LED light bulb with a Fresnel lens appears more similar to a

60° LED light bulb with normal opaque lens.

When lenses get exposed to heat and

light, the materials used degrades over time. The lenses become yellow, leading

to color shift, and due to this, the performance will vary between two

luminaries.

REFLECTORS

LED

reflectors are smooth, multifaceted inside, and come in different shapes. This

enables them to create a range of lighting effects. They collect and disperse

the light depending on their shape. Some reflectors contain a sub-lens, for

additional control of the light. A typical reflector comprises a polycarbonate

moulding with a metallised reflective coating. The metallised surfaces can

achieve high reflectance, although a lens ensures superior beam control. In

terms of cost and ease of manufacturing, reflectors are hard to beat but they

offer less control than LED lenses.

The

use of a reflector can also allow the elimination of the lens to reduce the

losses.

The

downside to reflectors is that the vast majority of light rays coming from the

central emitter pass through the LED light source without even hitting the

reflector. This means that a good portion of the light will stray wide off the

intended target, creating glare, and this is where TIR optics is required.

TOTALLY

INTERNAL REFLECTOR (TIR)

Designed around the phenomenon where

light travelling from one medium to another of lesser optical density hits the

interface at an angle and reflects with 100% of the beam energy, TIR optics, or

TIR lenses, consist of a refractive lens nestled inside a reflector and are

typically cone-shaped with optical efficiencies as high as 92%. The lens

directs light from the source’s centre to the reflector, which sends it out in

a controlled beam. An additional surface over the assembly provides another

opportunity to modify the light.

TIR optics is able to utilize the characteristics that are unique to LED.

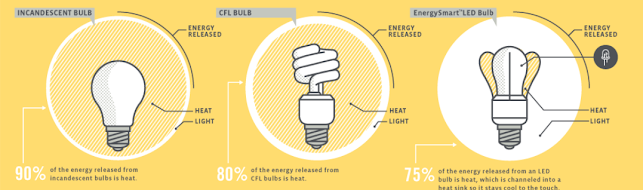

Unlike incandescent, who radiate heat

outward, LEDs send heat out their base, allowing TIR optics to fit tightly over

the top. TIR optics has proved prevalent in the outdoor and heavy duty space,

but hasn’t gained traction in forward projection applications. Optics has an

amazing ability to extract and control all of the light produced by solid state

lighting.

The

fundamental working principle is same for both TIR lenses and reflectors, but

the TIR lenses enjoy greater control over light. With reflectors, a large

amount of light doesn’t touch the reflector, and this light can’t be controlled

in any way. Reflectors can be easily implemented and cheaper to manufacture

than TIR optics, but the reflectors’ efficiency is clearly lower, compared to

TIR optics. A TIR lens manages both direct and reflected light, whereas a reflector

manages reflected light but leaves the direct light unmanaged.

The

TIR lens collimates the LED light into efficient, well-controlled light beams

that maximize the usable lumens in the target area with an absence of

discomfort glare or shadows. The result is a smooth, high quality beam of

superior intensity and uniformity, suitable for downlighting and directional

lighting applications. The narrow beam options are excellent for throw or

distance lighting, adding punch to Stage and Entertainment applications.

LIGHTING TRIM

In recessed

lighting fixture, the TRIM is the only component that we see with the naked

eye. The rest of the recessed lighting fixture is concealed behind your

ceiling.

Trim

refers to the light exit assembly that provides optical regulation and

aesthetical enhancement for a recessed downlight. The light exit assembly is

designed to maximize delivered lumens, shape the radiation pattern of LEDs,

conceal the LEDs from direct view, and seal the ceiling cut out for seamless

architectural integration.

The trim rests

inside of the housing and just out to form the outer ring, or moulding, of the

lighting fixture.

It

covers the point where the ceiling joins the downlight to create a smooth and

stylish transition between surface and light, being not only decorative but

functional

Some types of

trim include a fixture that can be adjusted to shine directly on different

areas of a room. Others have a protective outer cover.

Recessed lighting trims serve three

purposes:

- Ø They conceal the recessed fixture behind them.

- Ø They direct and shape the light downward.

- Ø They provide a finished/decorative look.

Types of trims to use for

various types of recessed lighting are as below:

Baffle trim:

Baffle

trims are the most common type of trim available for recessed lighting. This is

cone-shaped and made of metal. This type of

recessed light has grooves set into it, which are meant to block excess light.

This reduces

glare and shadows, so we can choose this type for a pure and soft ambient

light. It reduces eye strain, being pretty

comfortable and healthy. Due to the soft, gentle light it produces, baffle trim

is also popular in home office settings.

Black baffles

can reduce the glare further.

The

fixtures are suitable for task illumination, facilitating reading or sewing,

also for bedrooms, studies, nurseries. When you read or work on your PC,

smooth, flicker-free illumination is healthy. It reduces fatigue and eye

strain.

If

the ceiling in your living room is low, it might be a suitable option too.

Reflector trim:

A

reflector trim comes with smooth, polished-metal interior. They make it easy to

direct the lamps’ full output to certain areas. These fixtures maximize

brightness. So, they are used in places where extra amount of light is

necessary. This is

cone-shaped and made of metal.

Reflector

trims are used typically for commercial applications. Being essential in the

premises with high ceilings, like warehouses or workshops, hotels and offices,

they might be installed in various utility areas of your house, such as

bathroom or kitchen.

If

you install them in a small living room, you might feel uncomfortable.

Open Trim:

Open trim looks very similar to

baffle trim. The main difference is that it doesn’t have a ribbed interior.

The lack of ridges means that open

trim doesn’t prevent glare like baffle trim. The benefit to this type of trim

is brighter lighting. Open trim tends to provide much brighter lighting, to a

much larger area, than other types of trim.

Select a light color open trim (such

as white) to further enhance the brightness.

Open

trim lights are ideal for illuminating larger areas.

Eyeball Trim

Eyeball trim utilizes the same exterior trim as baffle trim and open trim, but pairs it with an adjustable interior light fixture. Sometimes referred to as adjustable trim, eyeball trim allows you to adjust the interior light fixture to customize lighting in your living spaces.

By

simply rotating the fixture, you can aim the light exactly where you want it to

illuminate. Their range of motion is typically 30° tilt and 359° rotation.

This

type of trim is perfect for accent lighting.

Wall Wash Trim

Wall wash trim is a combination of baffle trims and eyeball styles.

Though it doesn’t utilize interior ridges, it does have the same

exterior trim design as a baffle and open trim. Inside is an adjustable light

fixture that’s similar to eyeball trim.

There

is also a half shield that partially conceals the opening of the light. This

shield helps to evenly focus the beam of light on particular features in your

living spaces.

The

shield appears like a “scoop” to direct the light to a specific spot. These

types of trims are ideal for accent lighting and spotlighting artwork,

architectural features, or pieces of furniture.

For

example, wall wash trim is perfect when you want accent lighting to highlight a

painting.

Gimbal Trim

Gimbal trim functions almost exactly

the same as the eyeball trim type. However, the major difference between the two

is that the gimbal trim remains mostly flush with the ceiling. As a result,

when the fixture is pivoted, the housing will get in the way of some of the

light.

They are designed to be pivoted to

provide directional light. More specifically, gimbal trim recessed lights

direct downlight exactly where it’s needed. This type of trim is ideal for

sloped ceilings and for highlighting accent walls in a home.

Shower Trim

This

type of trim utilizes a tempered glass fixture cover. Not only does the cover

keep the light fixture safe, but it also keeps moisture out. Shower trim

recessed lighting is ideal for either wet or damp conditions.

Shower

trims are best for bathrooms or any other areas that experience levels of high

humidity.

Material :

You also have

two main materials to choose from, each of which helps give a certain design

aesthetic and comes with certain benefits.

Plastic: Plastic, usually of polycarbonate, is a very common lighting

fixture material. A basic plastic can work well in casual spaces. However,

there are ornamented plastic styles for more regal or upper-class looks.

Dark-colored plastics give a modern and sleek look. Plastic is also a good way

to keep the cost lower.

Metal: Metals can give an austere look that is great in modern or

industrial spaces. Steel is a very common material to find for its durability,

as is aluminum because of how lightweight it is.

Trim Colors

A trim’s color

can have a big impact on its output of the light. Dark colored trims absorb

light and can result in as much as a 44% loss in light output.

The term Photometric Efficiency is

used to describe the loss/efficiency of a trim.

Comments

Post a Comment